Areas of application

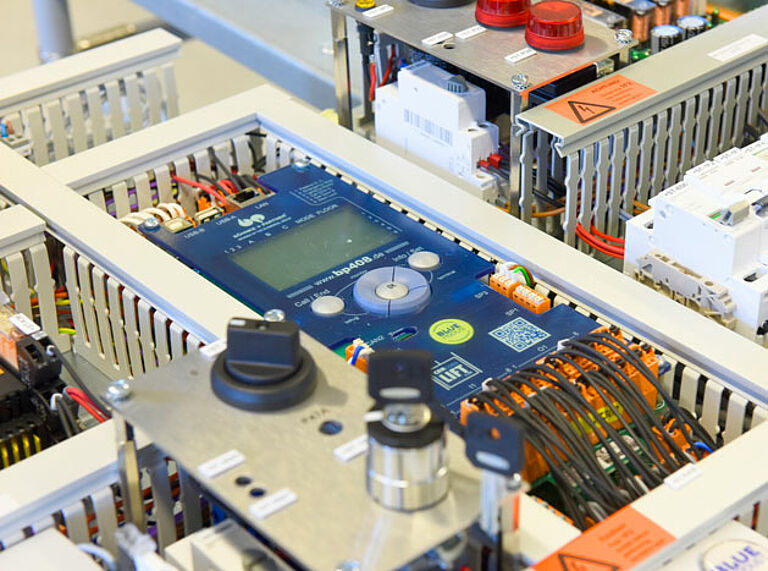

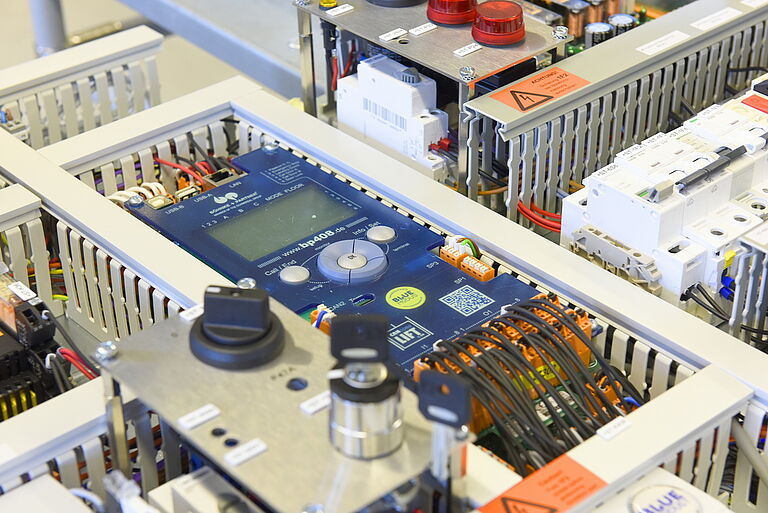

The central element of a lift system is the controller, which monitors and regulates the complex system – for the safe transport of people and goods. The bp408 control module is characterised by its compact design and wide range of functions, which enable it to be used in both traction and hydraulic systems in all common installation locations:

- Door frame

- Control cabinet for machine room-less systems

- Machine room control cabinet

Key facts

- Compact form factor

- Type tested safety circuit in accordance with EN 81-20/-50

- Can be used in traction and hydraulic systems

- Sophisticated group algorithm without separate controller

- Supports all types of shaft and cabin doors

- Integrated interfaces: CANopen LIFT, DCP, USB, Ethernet

- Supports absolute positioning systems (linear and rotary encoders)

- Supports Safety Position Units (PSU)

MODULAR EXTENSION

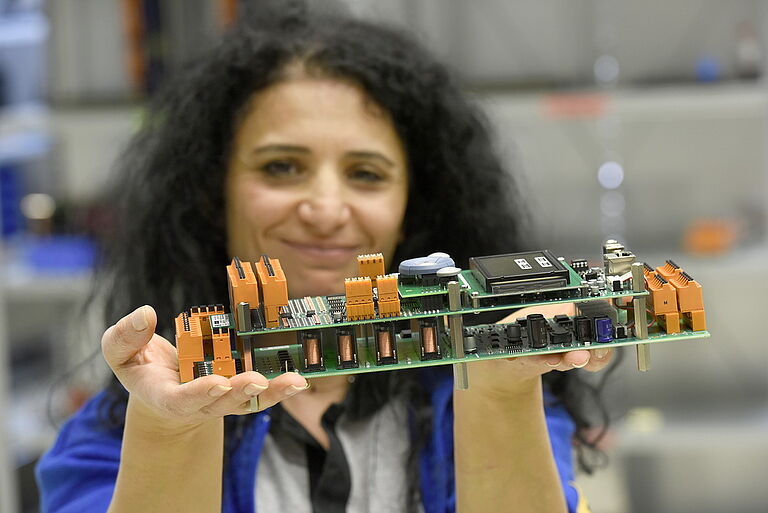

The bp408 control module is the next generation of the well-proven bp control concept from Schmersal Böhnke+Partner. The flexibility to meet the highest customer demands is supported by the established additional modules.

CIO – CANopen input/output module

The CIO module can be used to expand the bp408 control system by 32 additional inputs, outputs or calls.

CLK – CANopen car control board

The CLK car control board offers a wide range of options for car installations with 16 inputs, 8 outputs, 8 calls and 7 relays.

CLE – CANopen control board extension

With the CLE extension board, the CLK car control board can be extended by 32 inputs, outputs or calls.

CSI – CANopen serial interface

The CSI module is a CANopen bus node used to connect two bus lines.

CAP – CANopen landing call panel

The CAP is used to control landing call panels via the CANopen bus.

CBS – CANopen landing call panel

Works like the CAP, but is much smaller

CWI – CANopen wireless interface

The CWI module, in conjunction with the WinMOS®300 PC software or the WinMOS®300 app, enables wireless connection to the control system for operation using a PC or mobile phone.

CLOUD READY!

Many integrated functions:

- Safety circuit monitoring in accordance with EN 81-20

- Collective control

- Self-driver

- Priority and guest calls

- Functions for accessibility in accordance with EN 81-70

- Fire fighter lift in accordance with EN 81-72

- Fire alarm in accordance with EN 81-73

And many more

Special functions on request:

Solutions for car lifts, EX-proof systems, special systems for ships

Modularly expandable:

- Additional inputs and outputs

- CANopen LIFT components

- Load measurement, displays, panels

- Special gateways (e.g. Modbus, BACnet)

- Access control systems

- Transponder and card reader connection

Option of remote diagnostics and needs-based maintenance with WinMOS®300 and Lift2CLOUD®.

Technical features:

| General data | |

| Regulations | EN 81-1/-2; EN 81-20/-50 |

| Application range | Passenger and freight lifts |

| Haltestellen | up to 127 |

| Operating mode | Traction elevators regulated/unregulated |

| Hydraulic lifts regulated/unregulated | |

| Control type | Self-driver |

| One-button collective control (1 KS) independent of/dependent on direction | |

| Two-button collective control | |

| Self-driver with call memory | |

| Integrated group controller up to 8 lifts | |

| Electrical data | |

| Supply voltage | 24 V DC +10 %/-15 % (PELV) |

| Current consumption typ | 150 mA |

| Ports | 8 inputs, 24 V DC, input current 7 mA |

| 8 outputs, 24 V DC, output current max. 500 mA | |

| 16 inputs / outputs (calls), 24 V DC, input current 7 mA, output current max. 500 mA, protected from overcurrent and short-circuit | |

| PTC resistor input (PTC), 24 V DC, 1 mA | |

| Safety circuit inputs 48 V AC/DC, 110 V AC and 230 V AC, max. 2 A | |

| Safety circuit inputs 48 V AC/DC, 110 V AC and 230 V AC, max. 2 A | |

| 3 preselection relays (normally open contact), 230 V AC, 500 mA | |

| 4 freely programmable relays (changeover contact), 230 V AC, 500 mA | |

| Interfaces | CAN 1 (car), CANopen Lift (CiA 417) |

| CAN 2 (shaft/group) CANopen Lift (CiA 417) | |

| USB Host | |

| USB Device | |

| Ethernet 10/100 Mbit, full duplex (network connection) | |

| RS-485 (DCP) | |

| RS-232 (Gateways, e.g., for Profibus, Modbus, etc.) | |

| Indicators and control element | Graphic display with navigation keys: |

| second menu level and separate call menu | |

| permanent display of door status (max. 3), safety circuit, travel signal, lift state and direction independent of the menu | |

| Software | |

| Memory | Fault, maintenance, and message stack with max. 128 entries |

| Language settings | German, English, French, Italian, Swedish, Dutch, Spain, Portuguese |

| Groups | integrated group algorithms for up to 8 lifts |

| Functions | For comprehensive standard and special functions |

| Collective control / Self-driver | |

| Priority and guest calls | |

| Accessibility features | |

| Fire fighter | |

| Fire alarm | |

| Maintenance assistants | |

| etc. | |

| Remote-controlled control menu | Via WLAN/Ethernet with mobile device or PC with WinMOS®300 as APP or PC software |

| Backup/update | Backup and update via USB stick |

| Mechanical data | |

| Dimensions (H x W x D): | 315 x 100 x 80 mm |