Wide product range

Customised designs

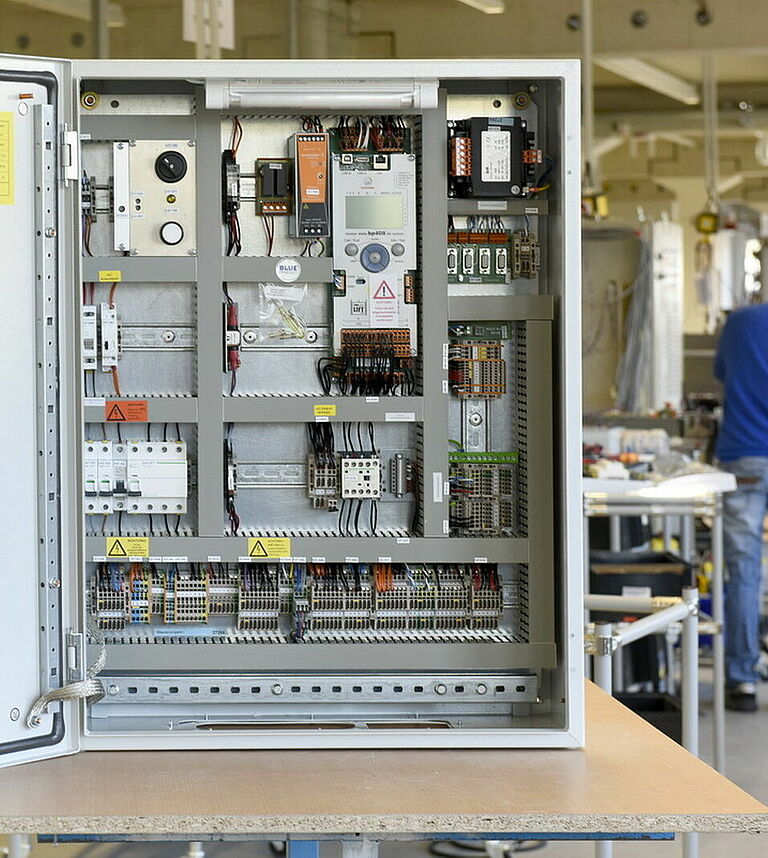

Schmersal Böhnke + Partner manufactures a wide range of products for its customers - from simple components to highly automated, complex lift control systems. Based on basic series, the control systems developed by Böhnke+Partner are individually adapted to the requirements of the lift system and the building technology and supplemented with additional functionalities and components such as inspection controls and emergency call systems. The software for the control systems is also developed in-house. This means that Böhnke+Partner is ideally positioned to support its customers in optimising their systems in line with the technological trends of the future.

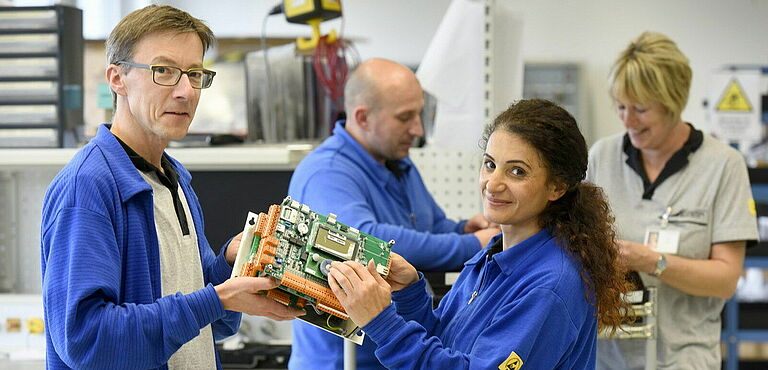

Support

by specialised experts

Each control unit is individually designed and manufactured for each project. Specialised experts support lift manufacturers in the design of special projects. A unique selling point of Böhnke+Partner is the consistent further development of the CANopen lift standard, which is mapped in every new generation of control units. Since 1991, every control system has been capable of monitoring. To this end, Böhnke+Partner is continuously developing its WinMOS®300 remote diagnostics software and offers Lift2CLOUD®, a cloud solution for remote maintenance.

Highest quality

The systems are mounted on round plates in the control system construction department. The control units are then wired and the individual parts are tested. Each control unit is fully tested using simulation software before being installed in the control cabinet. Special requests and customised products for customers are tested individually by hand. This guarantees the highest quality.

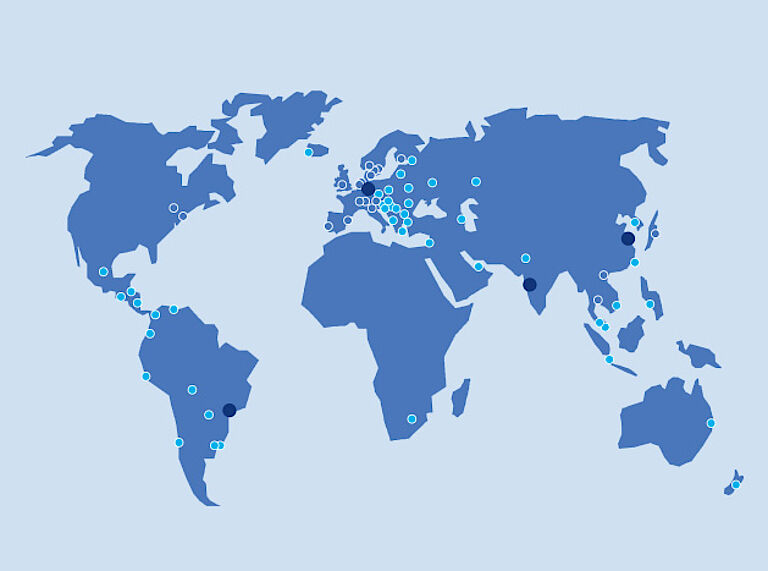

International presence

As a subsidiary of the Schmersal Group, Böhnke+Partner can also offer local production support in these countries via the Schmersal production sites in India, China and Brazil. The integration into the globally active Schmersal Group offers Böhnke+Partner the opportunity to be present in around 60 countries via the Schmersal branch network. In addition to the international sales network, Böhnke+Partner also benefits from the Schmersal Group's vertical integration with its own electronics and component production, which significantly increases the company's security of supply, especially in times of crisis.